Cooling System Troubleshooting

Revision D – 02/07/2009

The Miata cooling system is

described on pages E-2 through E-14 of the 1990 Miata Factory Workshop Manual,

and much of the material below, including illustrations, is taken from that

manual. Model years beyond 1993 have a number of differences, but the basic

troubleshooting procedures should be similar. Hopefully this article will be

useful to many of those having cooling issues. However, there is really no

substitute for the FWM if detailed information is needed.

A knowledge of what

conditions should exist in the cooling system is invaluable in troubleshooting.

So for the benefit of those who do not have a complete set of manuals for their

car, this article starts with a somewhat comprehensive set of desired cooling

system parameters.

Basics

Coolant Capacity and

Mixture

The cooling system capacity

is 6.3 U.S. quarts. MazdaÕs recommended anti-freeze solutions for the Miata are

as follows:

|

Minimum Temperature

|

Volume Percentage (%)

|

Specific Gravity @ 68¡F

|

|

Water

|

Glycol

|

|

-16¡C (3¡F)

|

65

|

35

|

1.054

|

|

-26¡C (-15¡F)

|

55

|

45

|

1.066

|

|

-40¡C (-40¡F)

|

45

|

55

|

1.078

|

Table 1. Coolant Mixture Recommendations (Mazda)

Remember that the primary

task of liquid cooling is to transfer heat energy from the metal parts of the engine

to the radiator and then to the air. Water has a specific heat of 1.00, but the

specific heat of glycol is only 0.571, meaning that a given quantity of glycol

will carry away only about 57% of the heat that the same volume of water will

transfer.

A more complete table of

freezing points vs. % ethylene glycol is given in the Handbook of Chemistry and

Physics:

|

Freezing

Temperature

|

Volume Percentage (%)

|

Specific Gravity

@ 60¡F

|

|

Water

|

Glycol

|

|

-3.9¡C (25¡F)

|

87.5

|

12.5

|

1.019

|

|

-6.7¡C (20¡F)

|

83

|

17

|

1.026

|

|

-12.2¡C (10¡F)

|

75

|

25

|

1.038

|

|

-17.8¡C (0¡F)

|

67.5

|

32.5

|

1.048

|

|

-23.3¡C (-10¡F)

|

61.5

|

38.5

|

1.056

|

|

-28.9¡C (-20¡F)

|

56

|

44

|

1.063

|

|

-34.4¡C (-30¡F)

|

51

|

49

|

1.069

|

|

-40¡C (-40¡F)

|

47.5

|

52.5

|

1.073

|

Table II. Freezing Point vs. % Ethylene Glycol

The boiling point of water at

14.7 psia is 212¡F, and if the pressure is increased, it rises. The pressure in

the Miata cooling system should be between 11 and 15 psi (25.7 to 29.7 psia)

maximum, which would place the boiling point of a 50/50 coolant mixture at

around 265¡F (at 15 psi) according to the Prestone labels.

Unfortunately I could not

find information correlating the ÒHÓ reading on the Miata temperature gauge

with coolant temperature. The 1990 FWM is written as though the Water

Thermosensor is the temperature gauge sensor, which it is not. There is no data on the actual gauge sensor, although the

manual spec on the gauge itself states that the gauge should point to ÒHÓ for a

resistance to chassis ground of 20 ohms (18 ohms for Canadian cars).

Coolant Flow

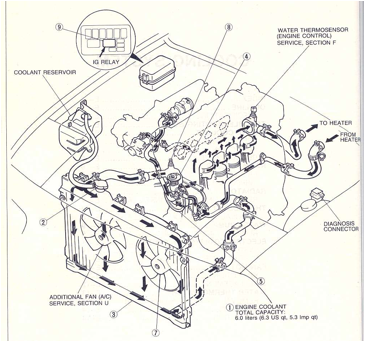

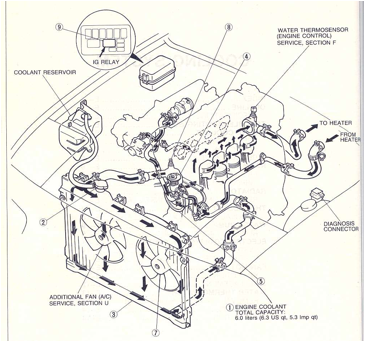

The coolant flow is shown in

Figure 1. The arrows clearly show the flow, but the diameters of the heater

hoses are actually considerably smaller than those for the radiator hoses, as

you can tell from looking at your engine bay. If the thermostat is removed,

flow will be unbalanced, since the water pump and the thermostat housing are

both at the front of the head. As a result, the rear cylinders will run hotter

than the front. The lesson here is to keep the thermostat installed; if you

have cooling problems, removing the thermostat is not a good long-term

solution.

Note that the diagram shows

an ÒIGÓ relay. That is actually the Cooling Fan Relay, as you can see on the

cover of the Main Relay and Fuse Box.

Figure 1. Coolant Flow

Note that there is no coolant

shutoff valve at the heater hose connections. Coolant always flows through the

heater core regardless of the position of the heater controls in the passenger

compartment. It is very important

that the heater core path from the rear of the head to the water pump inlet not

be blocked, since otherwise hot coolant in the rear of the cylinder head will

stagnate, making the rear of the head overheat.

Note the small hose at the

bottom of the thermostat housing that carries coolant output from the cylinder

head through the input side of the thermostat housing and down to the water

pump input. This assures that hot coolant from the head flows through the

thermostat housing when the thermostat is closed, exposing the thermostat valve

to the coolant. If this path is blocked by metal shavings in the thermostat

housing outlet nipple, or anywhere in the small hose, the coolant will not flow through, and the thermostat will not

open early enough. A symptom of a blocked path here would be temperature rising

above normal on first warm-up, then suddenly dropping to normal sometime later.

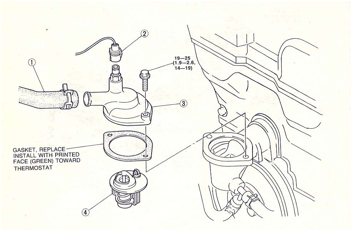

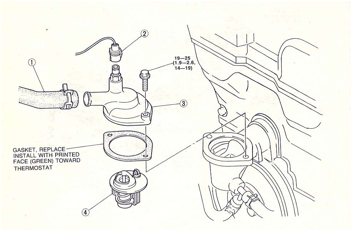

This connection can be seen in the lower right portion of Figure 2.

Figure 2. Thermostat Housing

Some coolant flows from the

cylinder head into the Idle Speed Control valve below the throttle body (called

the Idle Air Control valve on the 1.8L engine), then out of the ISC valve and

through the Air Valve mounted on the engine side of the intake manifold,

returning to a ÒteeÓ into the down tube from the thermostat to the water pump

input. (1.8L engines do not have an Air Valve.) The Air Valve on the 1.6L

engine is open when the coolant is cold, raising the idle speed, and closes

gradually as the coolant warms up to normal operating temperature.

Thermostat and Water

Thermoswitch

The OEM thermostat opens in

two stages. There is a Òsub-valveÓ that opens at 182 – 188¡F, and a main

valve that opens at 188 – 193¡F. As shown in Figure 2, the main valve is

oriented to the front of the thermostat housing. On the cover of the thermostat

housing is mounted a ÒWater Thermoswitch.Ó This switch is open when coolant

temperature is below approximately 207¡F and closed when the temperature is

higher. The closed switch activates the Radiator Cooling fan. If A/C is

installed, but not turned on, the A/C Condenser Fan (on the right side of the

radiator looking forward) will not

activate when the switch is closed.

Fan(s) and Fan Relay

The base Miata has one fan,

mounted on the left (looking forward) side of the radiator, called the

ÒRadiator Cooling Fan.Ó The Radiator Cooling Fan motor should use 5.3 –

6.5 Amps. If A/C is installed, there is a second fan on the right side of the

radiator called by Mazda the ÒA/C Condenser Fan.Ó The A/C fan motor is smaller

and the fan shroud fits on differently spaced mounting points, so the two fans

are not interchangeable.

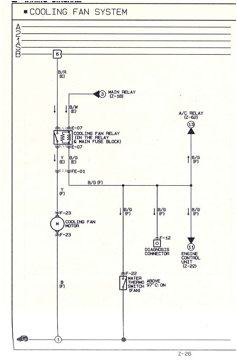

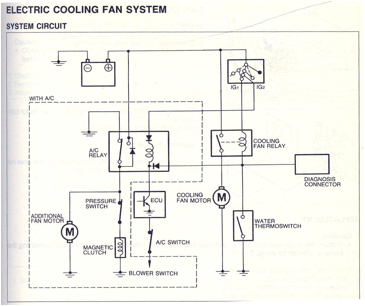

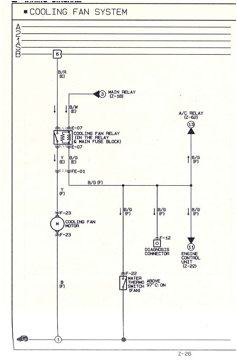

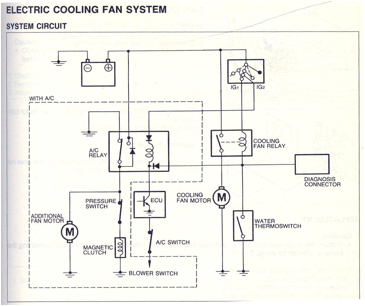

As seen in Figure 3, when the

Water Thermoswitch is closed, the Cooling Fan Relay contacts close and power

the Radiator Cooling Fan. The connection to the Diagnosis Connector goes to its

ÒTFAÓ terminal. If the ÒTFAÓ terminal is jumpered to the ÒGNDÓ terminal, the

effect is the same as closing the Water Thermoswitch, i.e. the fan should

activate if the ignition switch is on. This is a good test to determine that

the relay and fan motor are working. (This test will not activate the A/C Condenser Fan.)

If the test above fails to

activate the Radiator Cooling fan, then the 30 amp Cooling Fan fuse in the Main

Relay and Fuse Box is blown, or the Cooling Fan Relay or Main Relay has failed

open, or the fan motor is bad.

Figure 3. Cooling Fan Wiring Diagram

A/C Condenser Fan Circuit

The A/C Condenser Fan is

activated by the A/C on/off switch, on the heater/air conditioning control

panel. When the A/C switch is on, both the A/C Condenser Fan and the Radiator

Cooling Fan are activated by the ECU, through the A/C relay. Figure 4 shows the

wiring for this circuit.

Figure 4. Air Conditioning Condenser Fan Circuit

Radiator Cap

The OEM capÕs positive

pressure valve should hold closed until at least 11 psi and not more than 15 psi

pressure. The negative pressure valve should be easily opened with two fingers

and should seal closed when released.

Coolant Reservoir

This tank connects to the

radiator at the cap, just above the positive pressure valve. The tank is not

under radiator pressure. It should be sufficiently full to allow coolant to be

sucked back into the radiator as it cools off. If air is sucked in instead of

coolant, it will expand in the cooling system as the engine warms up, and will

result in air and coolant being expelled back into the reservoir if the

pressure is over 15 psi.

The small tube from the

reservoir input to the bottom of the tank sometimes gets clogged with rust or

other deposits from the cooling system. It should be cleaned for good operation

of the system.

The other tube from the

reservoir is an overflow to vent excess air and coolant. If the hoses are

removed from the reservoir cap, be sure to reassemble with the capÕs yellow tab

pointing toward the rear of the engine; the long tube connects to the radiator

hose.

Bleeding Air From the

System

Elevate the car on ramps or jack stands; this

will ensure that the cooling system radiator cap is above the thermostat

hosing. Drain the cooling system into at least a 3 gallon bucket and

flush the cooling system before installing any new components if possible.

Flushing the system will ensure that most of the contaminants are removed from

the cooling system. Most drain plugs are in the center of the radiator;

some may not line up with the drain plug opening in the plastic under-shield.

In that case, the shield has to be removed before draining.

Fill the radiator with the coolant mix until the

level is about 1/2 to 3/4 inch above the core and then start the

engine. Keep a bucket under the center of the car just in front of the air

dam under the front of the car. Run the engine, keeping this fluid level by

topping off occasionally. The engine will come up to operating temperature, and

the Radiator Cooling fan will kick on.

The system will overflow 2 to 3 times. Each

overflow should occur as the radiator cooling fans kick on so make sure you

have a bucket under the car. Cycle the system until it does not overflow

again. After each surge and overflow, refill the radiator with the engine

still running.

Turn the engine off and let it cool for about 1/2

hour. Then fill the radiator almost up to the water neck. Squeeze the

upper radiator hose to bleed out the excess air, and then top it off

again.

Install the radiator cap and run the engine until

the fans kick on again, then check for leaks.

Troubleshooting

Leakage

The OEM radiator is aluminum

with plastic end caps. With age, the black plastic will turn a brownish-green

color and develop the appearance of hairline cracks. At this time leakage may

begin to occur at the plastic/aluminum interface. Replacement of the radiator

is recommended if this happens.

The water pump may also begin

to leak, as evidenced by coolant on the lower front of the oil pan and/or

engine block. Again this usually means the pump is due for replacement,

although the pump gasket might be the culprit.

Any of the hoses shown in

Figure 1 can deteriorate and begin leaking. If a heater hose splits, be very

careful removing it from the heater interface tube, which is thin copper and

will deform easily. If the hose has to be replaced anyway, itÕs best to slit

the end of the hose along its length where it slides over the tube, instead of

trying to pull it off or pry it off. If the tube is deformed it may be prone to

leaking after hose replacement.

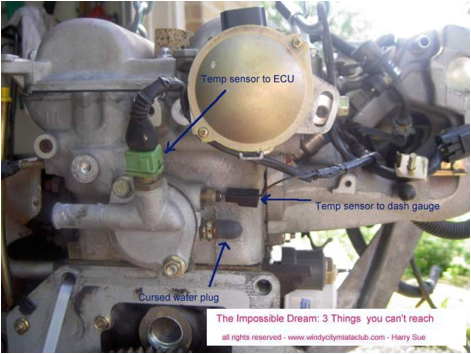

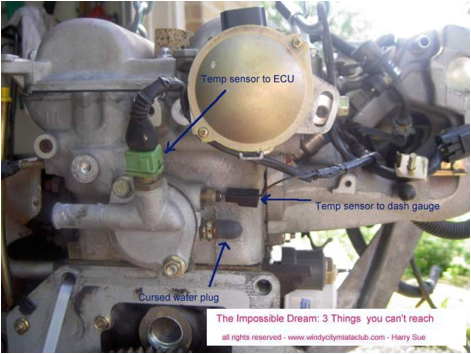

There is a rubber cap over

the end of an unused coolant tap at the rear of the engine block shown as

Òcursed water plugÓ in Figure 5 (Thanks for the picture, Harry Sue.)

This cap has been known to

leak and is difficult to trace, since it cannot be seen from the top or bottom

of the engine. To get at it with the engine in the bay, I think the CAS cover

has to be removed. However, I have never had to do this and I may be wrong

about that.

A hose leak at the rear

coolant housing generally requires the coil assembly to be removed before

trying to release the hose clamp.

Figure 5. Coolant Cap at Rear of Engine [Rev. D]

Overheating

Mazda states in the 1990 FWM

the following causes and remedies for overheating:

|

Possible Cause

|

Remedy

|

|

Coolant level insufficient

Coolant leakage

Radiator fins clogged

Radiator cap malfunction

Cooling fan malfunction

Thermostat malfunction

Water passage clogged

Water pump malfunction

|

Add

Repair

Clean

Replace

Replace

Replace

Clean

Replace

|

Maybe we can be more

specificÉ

Overheating at Idle

At idle, if the temperature

gauge indicates above normal, the Radiator Cooling Fan should be running. If

not, test with the ÒTFAÓ to ÒGNDÓ jumper in the Diagnostic Connector and see

whether the fan turns on when the ignition is on. If it does, the Water

Thermoswitch needs to be replaced, its connector needs to be cleaned, or its

wiring needs repair. If not, and there are no other problems with the engine

that are electrical in nature, either the Cooling Fan Relay (the ÒIGÓ relay in

Figure 1) or the fan motor is bad. Of course there is always the possibility of

an unplugged connector somewhere, or a broken wire. In a few cases the fan

blades had come loose from the motor shaft and were not turning, although the

motor was OK.

If the fan is running but the

engine still is overheating at idle, feel the top radiator hose. It should be

HOT! If not, the thermostat may be stuck closed. If it is hot, feel the bottom

radiator hose. It should be warm, but perhaps 20¡F cooler than the top hose. If

it is cool, there is blockage in the radiator, or possibly in the lower

radiator hoses, preventing flow into the water pump. Sometimes old bottom hoses

collapse under a vacuum created in them by the water pump straining to pull in

water at its input.

Finally, check to make sure

there is no blockage in the heater hoses, which would stagnate the water at the

rear of the head where the temp gauge sensor is located, and cause the

temperature there to be much higher than at the front of the engine.

Overheating at Speed

This problem, assuming there

is adequate uncontaminated coolant in the system, is either poor water flow

through the Figure 1 path, or poor airflow through the radiator.

Poor water flow can be caused

by a stuck thermostat (only partially open), collapsed hose, clogged radiator,

or a bad water pump.

Poor airflow through the

radiator can be caused by air blockage due to a license plate configuration,

bugs etc. stuck in the fins, bent fins due to mishandling, and in rare cases,

the Radiator Cooling Fan running backwards!

If all of the above items

have been checked and the engine still overheats, the cooling system should be

flushed to remove any scaling or corrosion inside the water passages.

Draining and refilling of the

coolant with a lower percentage of glycol in the mixture (see Tables I and II)

would help if the glycol percentage is too high (over 50%).

Also keep in mind that

temperature sensors and gauges do go bad occasionally. If the gauge says the

engine is too hot, but there are no other apparent symptoms like

lower-than-normal oil pressure, steam or bubbles escaping into the coolant

reservoir, or a very hot under hood temperature, maybe the gauge is giving a

false reading.

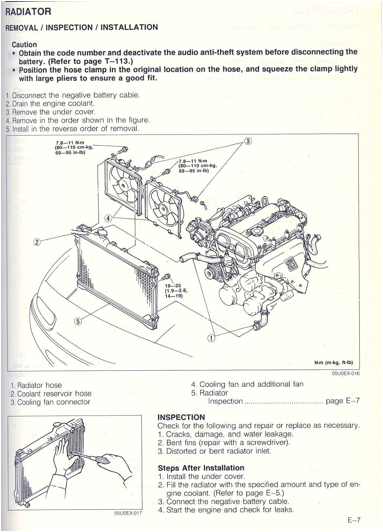

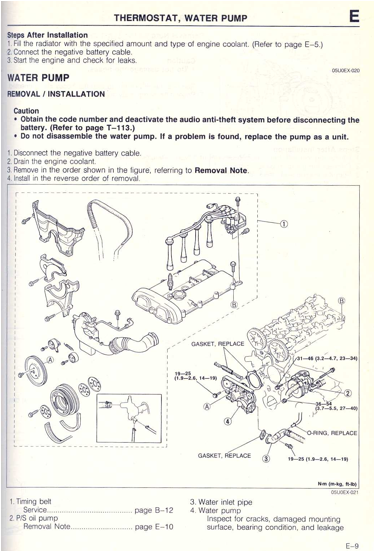

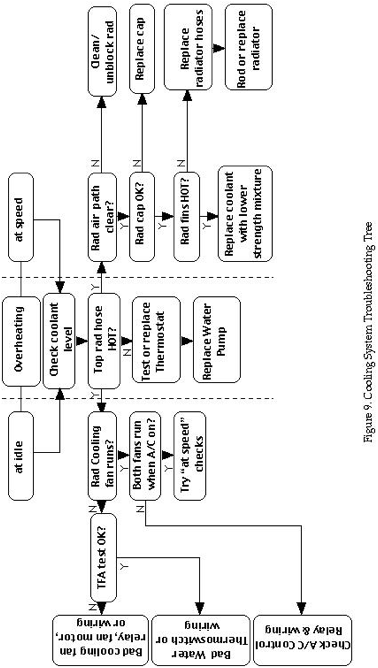

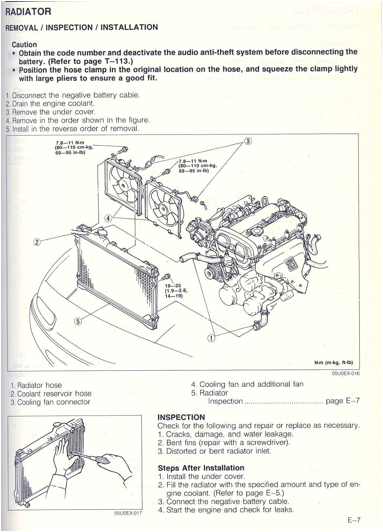

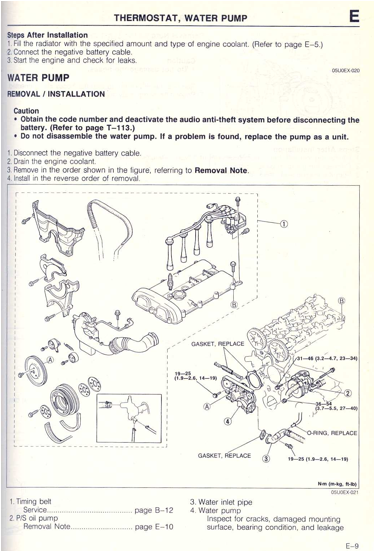

Figure 6 is a page from the

FWM showing radiator removal, and Figure 7 shows water pump removal. Figure 8

is a simplified block diagram of the electric cooling fan system.

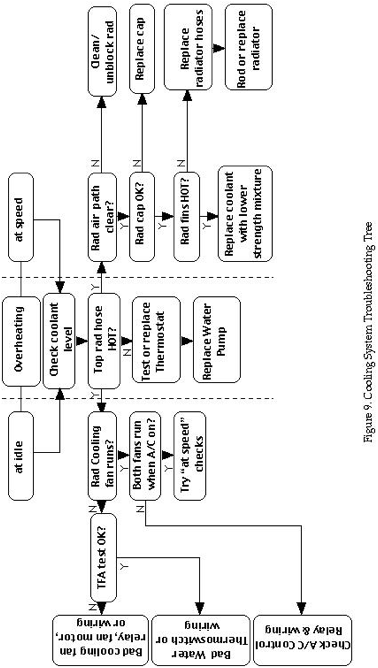

Figure 9 is a troubleshooting

tree for reference.

Figure 6. Radiator Removal

Figure 7. Water Pump Removal

Figure 8. Simplified Block Diagram – Cooling Fan

Wiring